Trakmaster 203

Click here to download technical information.

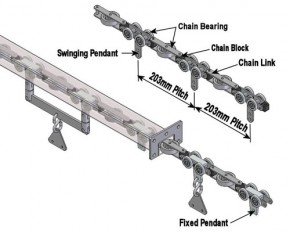

Chain

Fully bi-planer with a true pitch of 203mm. Single large diameter bearings are fitted between the horizontal chain links together with pairs of bearings on the vertical links.

Pendants are either standard free swinging on a single pair of wheels (23kg capacity) or fixed 6mm triangular plate with two pairs of wheels (35kg capacity). Again flightbars can be used across two pendants to double the load capacities to 46kg and 70kg respectively.

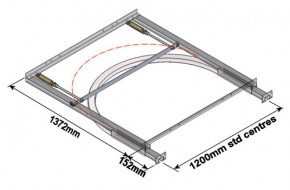

Track

Comprising a rectangular section 57mm wide x 41mm deep with a 3mm wall thickness and 19mm wide slot in the bottom face. Rolled in 6m long sections. The sections would be complete with joint plates for easy bolted assembly. Curves would be rolled and fabricated from standard track section and surface hardened after manufacture to give a long life.

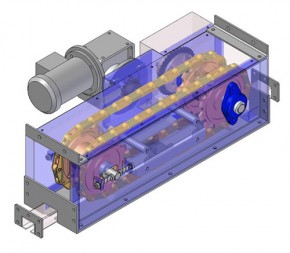

Drive Unit

Caterpillar type with driving dogs fitted between a twin pair of chains driven by geared motor unit and chain drive incorporating a torque limiter for overload protection. An AC inverter or DC thyristor can be used to control and vary drive speeds.

Tension Unit

A spring loaded tension device would be fitted to ensure correct chain tension and to compensate for variances within the conveyor system.

Inspection

This would be incorporated in a readily accessible position in the circuit for inspection and preventative maintenance.

Support Structure

The conveyor would be either floor supported using square hollow section forming a rigid structure and incorporating base plates, or roof supported utilising track hanger clamps connected to tubular suspensions. Please see specification for specific proposals.

Finish

Galvanised track, steelwork finished mid blue paint, machined parts self colour.