Is It Time For Some Conveyor TLC?

Regular service and maintenance of your conveyor belts and equipment will save you in the long run. Breakdowns due to infrequent servicing and lack of spares can lead to down time and major disruption. By ensuring your equipment receives regular service and maintenance you are sure to save yourself a lot of hassle.

If there is one thing our many years of experience here at Midland Handling Equipment Ltd have told us it is that even the most reliable and highest quality conveyors will eventually break down. Regular maintenance and servicing may be viewed by some as unnecessary, but the reduced output and capacity can cost a lot.

Planning Maintenance

Here at MHEL we offer full installation, service and breakdown cover for our customers. To ensure your conveyor system is running at full capacity and reduce unnecessary faults and damage, it is key that you regularly service the machine. Our trained engineers will ensure the machine is fully working and safe. If any issues are found, we are happy to quote to fix the fault for you. The majority of faults we find are able to be fixed on site and on the first visit. We also offer a ‘Service Contract’ giving you fixed service costs over the year (we would advise two services a year), priority breakdown response and 5% discount on spares.

Spare Equipment

It is advisable for customers to carry some spare equipment in the event of breakdowns. We can send you a list of essential spares for your system. Our conveyors are also backed by our comprehensive spares stock, quick delivery and fast breakdown response time.

Are you interested in acquiring a conveyor system for your workplace? Have you a system in place that requires servicing to ensure it continues to run smoothly in future? Or perhaps you wish to guard against future problems by acquiring some spare equipment for your system? If so, you have come to the right place. Contact the conveyor system experts here at MHEL for all your conveyor needs.

Three Problems That Will Bring Your Conveyor To A Halt

Material handling allows for a far more efficient transportation process of goods. Therefore the materials used in the transportation of goods are just as important as the goods themselves. Without the proper implementation of a good quality, robust and sturdy handling system there is the potential to slow down or even completely stop the process, causing multiple problems. Naturally, the materials used in conveyor systems will after a long period of time begin to show signs of wear and tear, with the potential to cause down time. Regardless of the type and uses of your conveyor, eventually it may encounter problems such as rust, corrosion, stiffness and a fall in the productivity of the machinery. So what are some of the problems that will bring your conveyor to a halt?

Problems That Will Bring Your Conveyor To A Halt

Mistracking

Designating and ensuring a belt stays on a specific path is known as conveyor belt tracking, and this is crucial in maintaining the output of your system. When a belt moves from its true course this is known as mistracking. This can lead to problems such as belt and product damage, with the likely result being downtime. Ensure you keep your machinery in top condition to prevent this from occurring.

Blockages

The main purpose of your conveyor belt is to efficiently move products. When there are problems with the system, such as sharp ridges or rigid directional changes, there is the potential for blockages. This again can lead to downtime, seriously impacting your efficiency. Thorough maintenance and supervision of your system will prevent this problem from occurring.

Seized Rollers

Most conveyors use metallic elements such as steel which is often used in rollers. After a long period of use these have the potential to develop sharp edges. This poses a danger to both safe working conditions and the goods being transported. Similar to other problems, thorough maintenance and supervision will allow you to identify these problems early and rectify them before it has a significant impact upon efficient and output.

Conveyor Maintenance

Thorough surveillance and maintenance of your material handling systems means you can identify problems early and save yourself both money and a fall in output in the long run. If not there is always the potential to encounter problems such as mistracking, blockages and seized rollers. If you are experiencing any problems with your conveyor systems, contact the material handling experts today!

The Main Types of Conveyor

There is a wide range of conveyor belts available on the market. Many of these vary and can be created bespoke to suit the individual requirements of one’s workplace. Understanding what conveyor belts are available on the market can be quite a confusing and daunting task. That is why here at MHEL we have compiled a list of the main types of conveyor on the market to make your task just that little bit easier.

What Are The Main Types Of Conveyor?

Belt conveyors – belt conveyors are the most well known form of conveyor belt. They are a simple strap mechanism to keep things flowing without the need for manual labour. There are two or more rollers with a belt tensioned between the two. One of these rollers will be powered and allow the whole belt to move.

Mesh belt conveyors – these consist of woven metal that creates a mesh belt. They can be a wide opening or a small opening mesh on requirements. Mesh belt conveyors are lightweight so good to use for food and especially effective as oven conveyors.

Stainless steel conveyors – stainless steel conveyors are another type of conveyor and are usually good for us in pharmaceuticals or food industries as they can be sterile clean, and therefore extremely hygienic.

Gravity rollers – gravity rollers are a type of conveyor that can move with the movement of products. This means there is no need for motor power sources. They basically consist of numerous rollers that allows the products to slide over them. If the gravity rollers are on a decline the products will move automatically. If the rollers are flat it would require manual input to move the products.

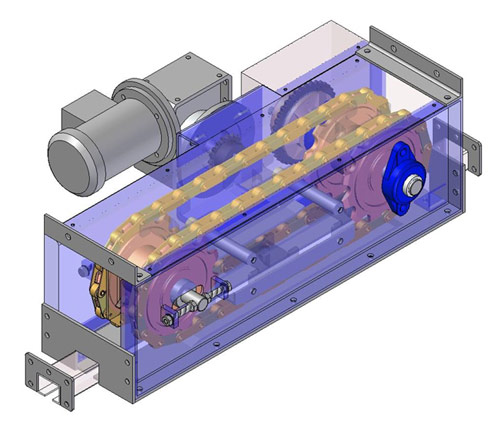

Chain driven rollers – chain driven rollers are useful for when you require a little bit more power. Standard rollers allow items to ‘slip’. However if a product requires more power to move this is where chain driven rollers are useful. If heavy objects need to be moved each roller is bound to the next by a chain and creates ‘driver rollers’.

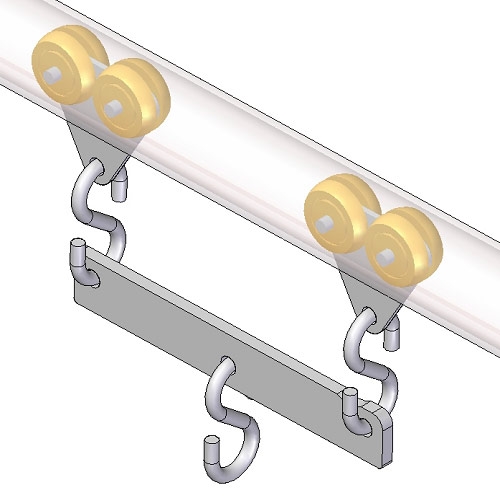

Free track conveyor belts – free track conveyor belts allow a low-cost solution to handling problems. They are simple in that they basically consist of a trolley style carrier powered by gravity or hand.

Slat belt conveyors – slat belt conveyors are useful when belt or roller conveyors are not suitable. This may occur when there are high temperature ovens, heavy products or dirty and arduous conditions. Slat belt conveyors are made of steel, hardwood or plastic are fitted to make a moving ‘table’ surface.

Plate link conveyors – plate link conveyors are made from metallic or rubber plates. They are similar to slat belt conveyors in how the plates over link one another. Metal plate link conveyors are especially useful for high or low temperatures that would damage rubber or fabric belts or plates.

Powered monorail conveyors – powered monorail conveyor systems consist of a conveyor chain that is supported above head height via floor stands to maximise floor space below. It allows workers to inspect and treat products while it is hanging over the factory floor. This allows greater productivity and efficiency. This is especially useful in shot blasting and powder coating as each angle can be approached easily without endangering employees.

Power and free – power and free is the name applied to an overhead chain system which has the ability to provide specialised zones to buffer storage for loads. This would be impossible on a conventional overhead conveyor without stopping the entire system hence causing disruptions and affecting productivity and efficiency.

Bottle conveyors – bottle conveyors are useful for applications such as blow moulding or filling and packaging bottles. Bottle conveyors are available in various speeds to allow various drinks production lines.

Types Of Conveyor Belts

As you can see there are many various main types of conveyor belt available on the market. The right kind of conveyor for you is dependent upon many conditions. Various circumstances must be considered. What kind of materials will you be transporting? How much room have you got available? What kind of heat will you be dealing with? Here at MHEL we are experts in conveyor systems and material handling. Get in contact today for a quote.

Aston Martin – Power & Free Conveyor

Midland Handling have one their second order of the year to supply an over power and free conveyor to Aston Martin. The contract is with Exmac Automation and incorporates a 224m assembly line for car doors.

Automated Material Handling Equipment Global Size Will Be Worth USD 47.6 Billion by 2023

A great deal of business is looking to make their manufacturing and handling processes more seamless and efficient through the use of handling equipment. Companies considering this move have over the years invested in automated material handling equipment like robots, conveyors and sortation systems.

The growing demand for automated handling system is expected to drive the growth of the market which is expected to reach about USD 47.6 billion in 2023 from the current USD 30.5 billion representing a 7.68% growth of the CAGR.

The recently released automated material handling equipment report bases the findings on a variety of factors including the application of the equipment, the main players in the industry, the type of product and the geographical location.

The research is based on data related to profiles of some of the leading companies in the sector, the year they were established, their headquarters among other factors and recent development.

Geographical Region

The global Automated Material Equipment market report highlights various regions like Latin America, North America, Africa, United Kingdom, The Middle East, Europe and the Asia-Pacific. The report heavily relies on a variety of factors like market strategies, dynamics and demand and supply. The report has also gone to great lengths to track the existing trends in the market, technological developments, major challenges and opportunities.

Key Players

The report also offers an inclusive inside look through a thorough analysis of the competent player in the different sectors both independent and dependent. Some of the accurate findings provided by the report include the research findings, the Automated Material Handling Equipment market statistics as well as upcoming aspects of the market. All this information is collected through primary and secondary research methods which include interviewing the Automated Material Handling Equipment market experts. The report also includes insightful information in form of tables, graphs and pie charts and other forms of statistical data available in the field.

Points to note in the report

Other than the projected figures and the growing trend of the industry, there are a variety of other key points that are worth noting contained in this market report. These include;

The report offers an in-depth peer to peer analysis of the changing trends in the market, the dynamics of the market and the competitive market.

The report forecasts growth of the market over the next five years and provides a clear vision of the trends, the restraints and the driving factors and trends that will fuel the growth. The report also offers an understanding of the Automated Material Handling Equipment market and the key products.

Another highlight of the report is the focus on market dynamics and future trends and the competition of the key market players which is an eye-opener for players that are joining the market or those that are looking to take full advantage of the growing market.

The Automated Handling Equipment report ultimately provides market players with accurate information to make business decisions and other technical aspects.

Aston Martin – Powered Overhead Order from Exmac Automation

We have secured another order from our good friends at Exmac Automation to provide and overhead conveyors system in Aston Martin’s plant in Wales. The Trakmaster 406 conveyor will be an indexing conveyor between stations for instrument panel assembly.

JLR Solihull – Conveyor Components Order from ExMac Automation

Midland Handling Equipment have won an order from Exmac Automation to supply an overhead power and free conveyor to be installed into Jaguar Land Rover’s plant in Solihull.

ExMac Automation are a specialist materials handling provider to the automotive industry and will install our Trakmaster 406/406 conveyor components as part of a turnkey package for JLR radiators.

Envirotrak Conveyor for Dewit Garden Tools, The Netherlands

Midland Handling have secured an order to supply a 304 Envirotrak conveyor to Dewit Garden Tools in Kornhorn, The Netherlands.

The conveyor is part of dipping process for the tool handles. The order was courtesy of our German agents EngMec.

Free Track Conveyor for Shelbourne Reynolds Agricultural Machinery

Midland Handling have just won a contract to provide Shelbourne Reynolds with a new heavy duty free track conveyor. Shelbourne manufacture heavy agricultural machinery and have been a good customer of Midlands since mid eighties when we installed our first system at their site near Bury St. Edmunds.

Due to the requirement to powder paint much heavier loads we are providing a twin channel free track system with 10m loadbars capable of taking loads up to 4500Kg. This will replace the existing Trakmaster 406FT conveyor which we will dismantle during the installation.

Hannover Messe – 24-28th April

We have a stall at the Hannover Messe with our Partners Eng-Mec. Come see us on hall no. 25 stand no. H14 24-28th April