Conveyor Systems

Overhead Conveyors

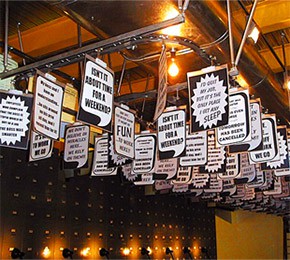

We are the number 1 provider of Conveyor Systems, Overhead Conveyors and Overhead Trolley Systems in the Midlands. Here at Midland Handling Equipment, we excel in this area producing a broad range of Handling Equipment and Factory Automation to resolve most manufacturing or display problems in a safe and efficient way. Conveyor Systems are used across the UK and worldwide, with various methods for each system, for example, Overhead Conveyor Systems have been used in numerous applications including shop displays, assembly lines and paint finishing plants.

Our extensive range of Conveyor Systems includes traditional Gravity Roller Systems & Powered Roller Conveyors as well as conventional Belt Conveyors. We also manufacture Slat Conveyors, Plate Link Conveyors, Powered Monorail Systems, Mesh Belt Conveyors which are all ideal for warehouse logistics, storage solutions, recycling and waste disposal uses as they are created for heavy loads of various loads. With Health & Safety and efficiency becoming vital in today’s competitive industry, it is imperative to provide Factory Equipment that protects and aids its operators in the best possible way which is why we also provide Lifting Equipment and Safety Gates to ensure ultimate security for all staff member.

As well as manufacturing the conventional Conveyor Systems, we also provide Inverted Chain Systems such as Inverted Power & Free, Inverted Monorail which can be used as Bottle Conveyors. Whatever your requirement is, if it’s to do with the Conveyor Systems, you should be able to find a solution on our website. However, if your solution isn’t obvious, please don’t hesitate to contact us.

Having the ability to provide and install large turnkey projects yet still accommodating the smallest of jobs is an example of our versatility here at Midland Handling Equipment. We are a long-serving and respected member of AMHSA & BMHF, which is further proof of our position as one of the leading Material Handling Companies worldwide.

Handling Equipment Solutions

Creating Production Line Automation

At Midland Handling Equipment, we have access to a wide range of CAD programmes in the design office to produce in-depth, detailed 3D drawings. The drawings we produce allows us to troubleshoot any problems when creating production line automation before we start manufacturing them. Our in-house Design Engineers and Technical Experts work together to provide high-quality and efficient solutions to the hardest of problems. After we have the design, our team of Mechanical Experts and Electrical Engineers work together on the finishing of products. The final stage, if required, is the installation process which is completed by our Installation & Commissioning Teams.

We are fully trained and certificated for all types of lifting equipment and carrying platforms, which helps aid a fast but safe installation of your Conveyor System. Finally, the accounts and administration are handled in our ground floor department providing all financial, health and safety, and legal documentation to the required standards.

Conveyor Belt Manufacturers

Production Line Automation is a great way to cut costs and improve quality, consistency and delivery, however, it can also turn out to be a disaster if you don’t have the right partner. So, why are we the best partner for you?

Comprehensive Service – All our teams are in-house, from the design and drawing to testing, production, installation and administration, everything is under one roof! This helps to cut the production time, improve accountability and provide you with a worthy experience while working with us.

Trained & Certified – With the future of your business on the line, you want the best-qualified minds working on your project. Our team are Trained & Certified in manufacturing and installing a variety of complex Conveyor Systems and Lifting Equipment.

In-House Testing – Testing a system before delivering is standard and a very important step we take here at Midland Handling Equipment as it helps to identify areas of fault or weakness. We do all our testing in-house which allows for thorough testing, it’s also easier to make corrections. After testing, we have a team of Mechanical and Electrical Engineers who install these finished products.

Documentation – Our Administration Team will present you with all the Legal and Health & Safety documentation that is required for your Conveyor System or Platform. All that is left to do is put the system to work.

For more information on our Conveyor Systems please see the menu bars above, or get in touch with our friendly team today on 0116 259 3175.